Welding processes for joining plastics are numerous – a selection is listed below.

1. Laser Welding or Laser Beam Welding (LBW)

Also known as Laser Beam Welding (LBW) this welding technique is used to join pieces of thermoplastics using a laser. The laser beam delivers a concentrated heat source permitting narrow and deep welds with high welding rates whilst the two parts are put under pressure. Speed and precise control are two of its many benefits.

2. Ultrasonic Welding

Ultrasonic plastic welding is a commonly method that has been in use for a long time. It uses the heat generated from high-frequency mechanical motion to join thermoplastics. It happens by transforming high-frequency electrical energy into a high-frequency mechanical movement. You can use ultrasonic welding on almost all plastic material. It is known for being affordable, clean and meeting quality requirements.

3. Hot Gas Welding

A commonly used welding process for the manufacture of smaller items (heat exchangers, chemical and water tanks…), hot gas welding used a specially designed heat gun. The hot air that the gun generates softens the plastic parts to be welded and the plastic filler rod which needs to be of same or comparable plastic material. Also added to the weld joint in addition to the hot gas is a plastic filler material to aid the bonding process.

|

| Ads |

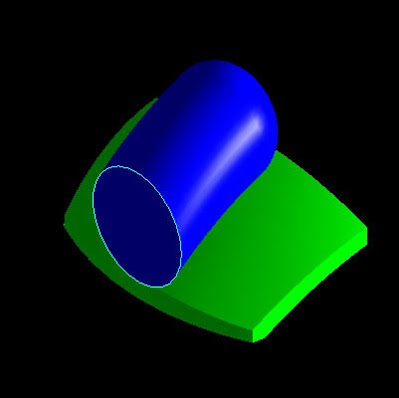

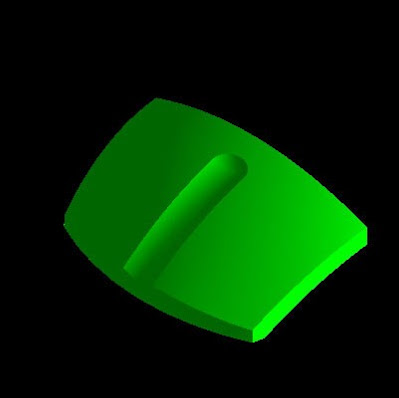

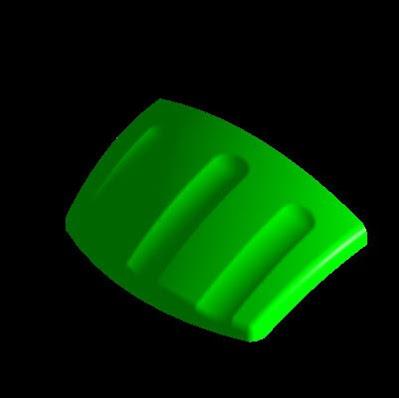

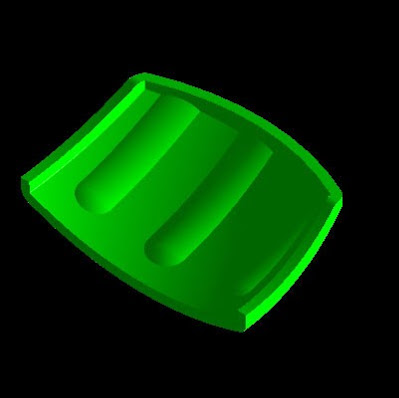

4. Spin Welding

For the joining of plastic components, spin welding uses surface friction focussed in a circular weld joint. It produces the heat needed for the melting of the surfaces to be joined by spinning one of the parts relative to the other. The two parts are held under a controlled load. When the spinning stops the joint will be left to cool.

It can be used to weld plastic components of big sizes and is a fast process but one of the parts needed to be circular. One of its uses is the sealing of containers.

5. Vibration Welding

Vibration welding, also called linear or friction welding, is when two plastic pieces are connected under pressure. The heat is generated when a vibration is used along the common interface. Compared to hot plate welding, it is much faster and more accurate.

6. Hot Plate Welding

One of the oldest process, this is a thermal welding technique used for joining thermoplastics. In order to melt two surfaces, a heated metal plate is placed against or near and the surfaces are connected together under pressure. This method is simple and produces strong joints in most all thermoplastics so it is commonly used in the mass production or large structures such as plastic pipes of large diameter.

7. Friction Welding

Friction welding of thermoplastics is often employed for joining injection-moulded parts and was established some time ago. It uses friction to produce heat and to join two pieces together. Friction welding delivers many benefits to manufacturing and is often used in the aerospace and automotive industries this technique to join metals and plastics.

8. Frequency Welding

This plastics welding technique, also known as high-frequency welding or radio-frequency welding, uses electromagnetic field to join two plastic parts. The high-frequency electric fields are used to heat the material and pressure is also added to soften and join the two materials together resulting in a strong bond. Polyurethane and PVC are welded with this technique.

Where is it Used?

There are many types of plastic and it is a versatile material used in a wide range of sectors such as packaging, electronics, construction, fabrication, medical, aerospace, automotive and many other industries. When correctly applied, plastics welding can be enormously strong.

Some video:-